PMT

| Availability: | |

|---|---|

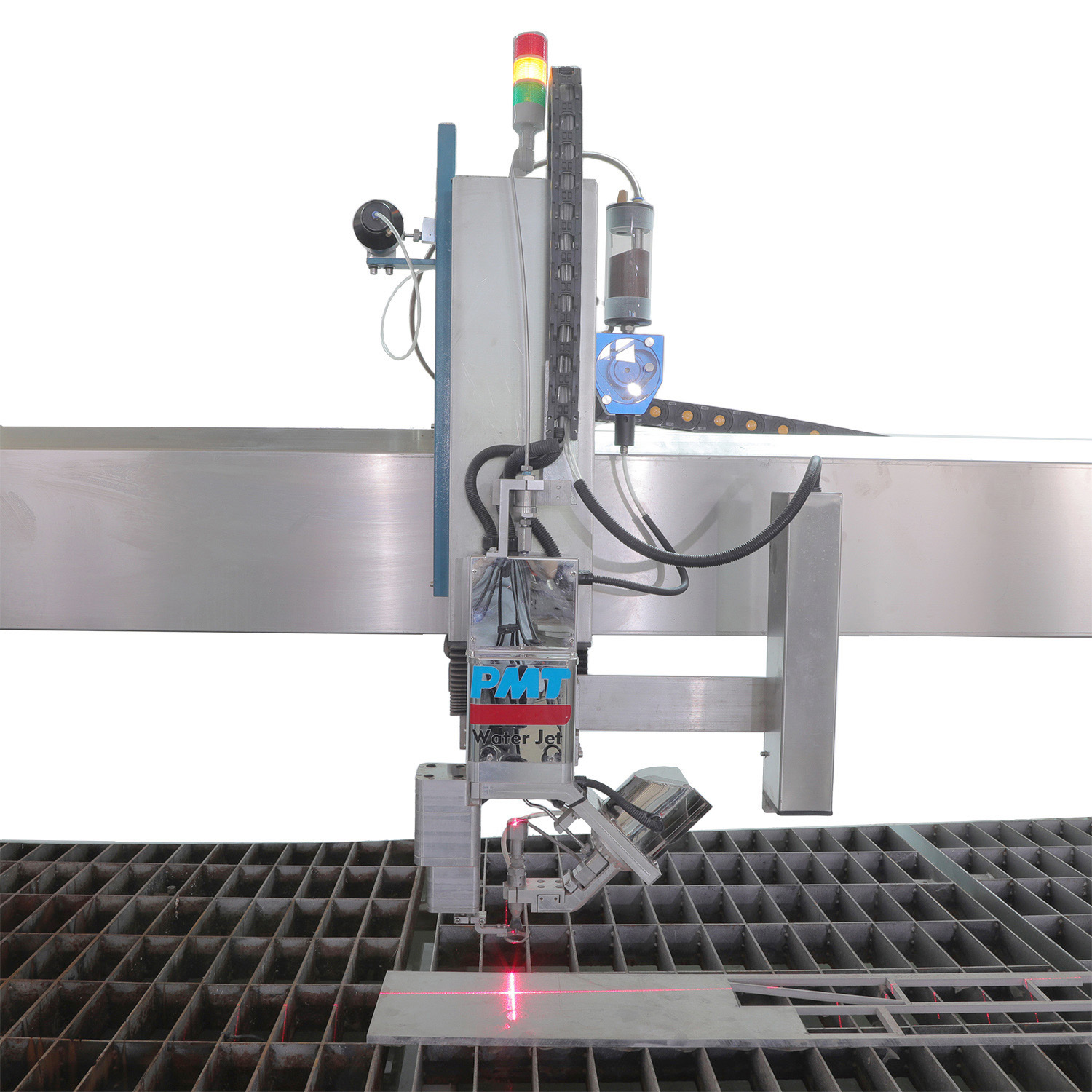

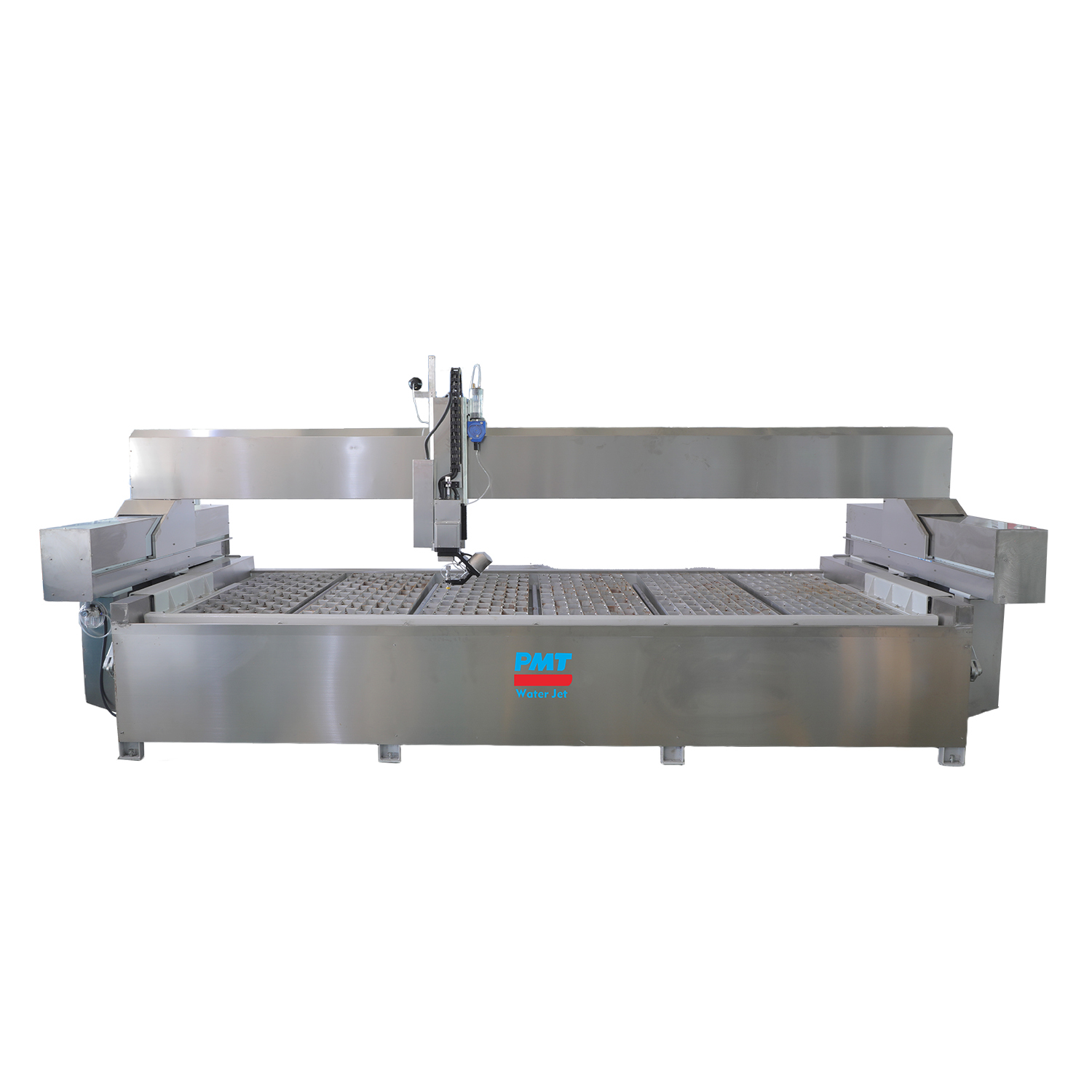

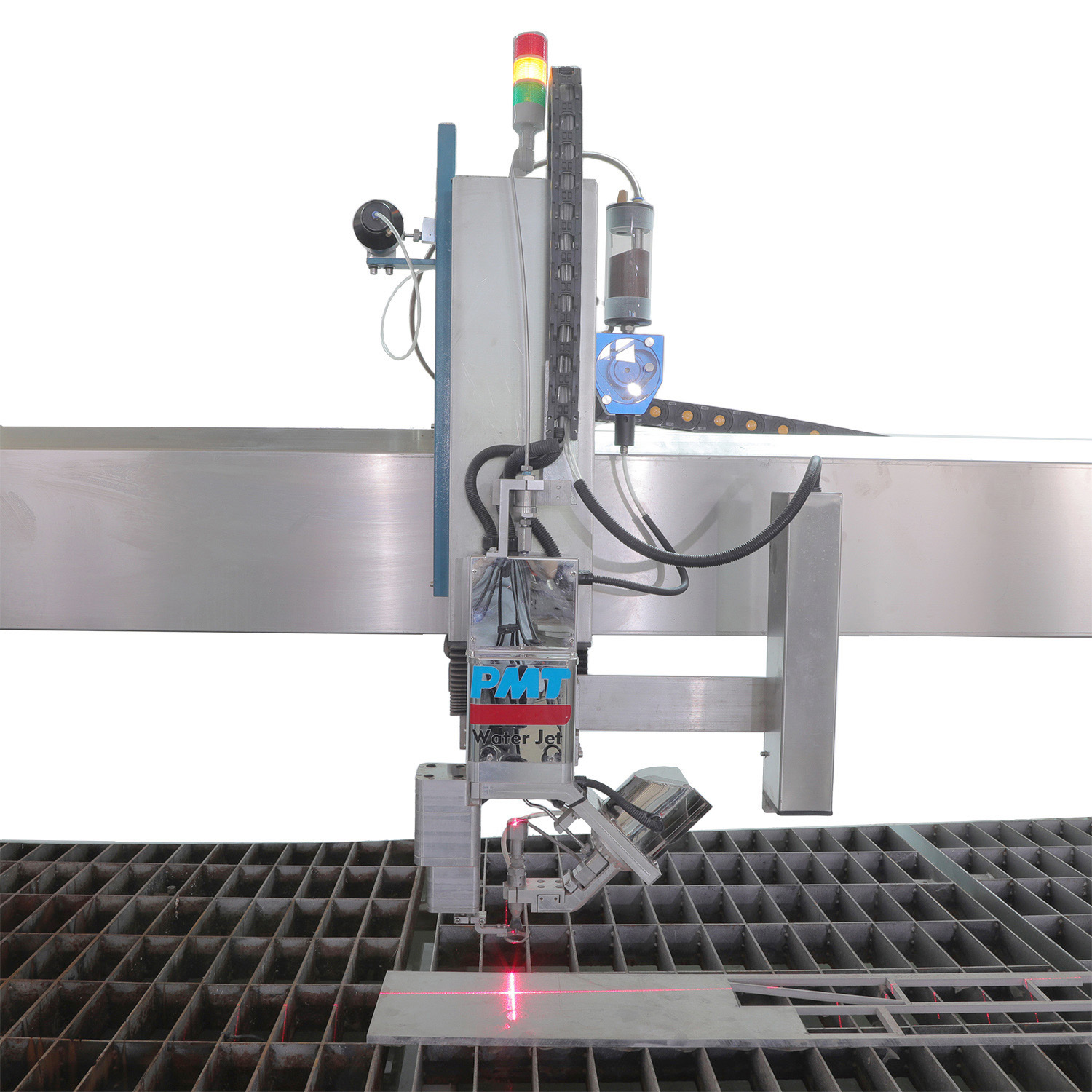

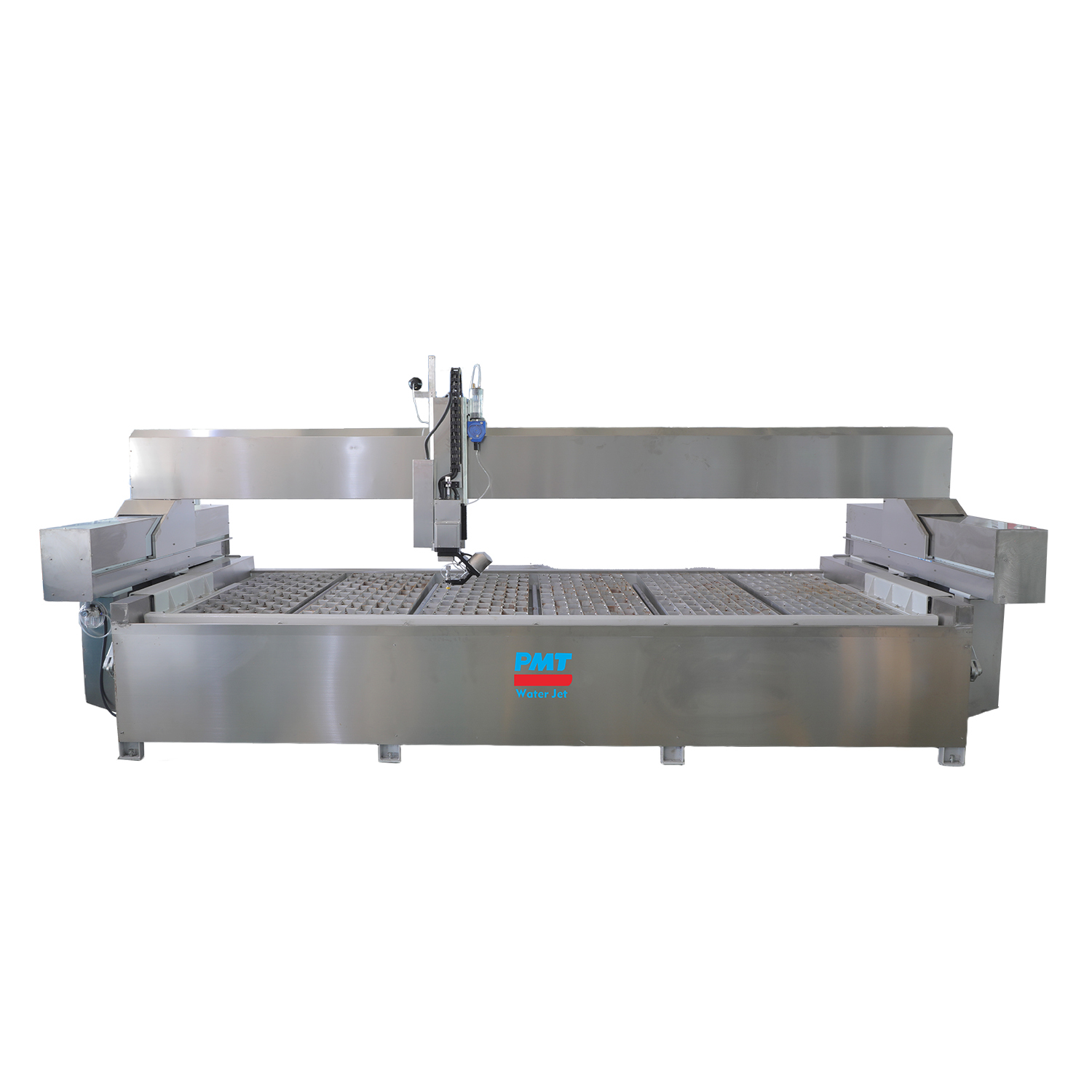

One standout feature of the PMT Waterjet Cutting Table is its gantry mechanical structure. This design is perfectly suited for large-sized machines, allowing for extended travel distances along the X and Y axes. This versatility makes it particularly suitable for processing a wide variety of complex, oversized parts. Whether you're tackling intricate designs or sizable projects, the PMT Waterjet Cutting Table is up to the task.

PMT waterjet cutting machine Advantage

1.Smooth cutting quality is perfect.

2.The cutting accuracy of waterjet cutter is up to 0.1mm. Edge joints are regular, and waterjet cutting can also make very complex puzzles and murals.

3.Cutting speed is fast, and product consistency and interchangeability are very good.

4. Drilling, cutting and forming can be done at once.

5. Improve the working environment and reduce the impact of dust and noise on the operator.

6. Waterjet cutting is a cold cutting that does not damage the internal structure of the material.

7. It is the only machine for processing composite materials and fragile porcelain.

8. Waterjet Cutter can cut metal, rubber, foam, plastic, composite materials, stone, ceramic tile, marble,glass, etc.

About size, we have 4000*2000 mm , 3000*2000mm , 2000*1500mm , 2500*1500mm , 6000*2000mm ect, which you want?

Our laser edge finder, which slides over the focusing tube, allows the machine operators to rapidly establish exact location points, edges, centers of material, and centers of holes of pieces being cut on their Semyx Cutting Solutions' table.

1. Working Table & Controllor

The cutting table is a computer-controlled 2D table, featuring the Y-axis, catcher, X-axis, Z-axis (cutting head holder), cutting head, high-pressure hose, and the abrasive box. Both the X-axis and Y-axis are equipped with linear guides and ball screws for precise motion control.

Model | 2015 | 2515 | 3020 | 4020 | 6020 |

Dimension(mm) | 2650*2150mm | 3100*2150mm | 4500*2300mm | 5250*2300mm | 7000*3100mm |

Max. cutting range | 2000*1500mm | 2500*1500mm | 3000*2000mm | 4000*2000mm | 6000*2000mm |

Travel of Z axis | 180mm | ||||

Servo system | Weihong,OEM Panasonic | ||||

ball-screw linear-rail | ABBA/TBI,Taiwan Brand | ||||

Re-positioning accuracy | ±0.025mm/m | ||||

Cutting accuracy | ±0.1mm | ||||

Max. running speed | 15m/min | ||||

lubrication | Oil Immersion | ||||

Material | 203stainless steel material tank,cast steel beam,rubber and stainless steel cover | ||||

2. Feature

The guide rails and ball screws of our waterjet cutting tables are fully immersed in an oil tank, ensuring optimal lubrication and preventing wear caused by abrasive materials and water splashes. This unique feature not only guarantees exceptional cutting precision but also significantly prolongs the machine's lifespan. It effectively addresses the issue of accuracy deterioration commonly observed in conventional water jet cutting machines. Furthermore, our cutting technology ensures consistent accuracy regardless of the time of day.

1.Enhanced Stability: Our waterjet cutting tables employ an oil-immersed transmission mechanism that offers superior stability compared to traditional transmissions. This advanced system enables precise control over cutting speed, pressure, and direction, ensuring optimal performance.

2.Reduced Noise: The oil-immersed transmission mechanism utilizes high-quality finished oil for lubrication. Unlike the grease or liquid lubricants used in conventional mechanisms, finished oil provides superior lubrication effectiveness while generating minimal noise. This results in a quieter operation during the cutting process.

3.Convenient Maintenance: Our waterjet cutting tables equipped with an oil-immersed transmission mechanism require simplified maintenance compared to traditional systems. The long-lasting lubrication effect of the finished oil significantly reduces the frequency of oil replacement, resulting in lowered maintenance costs.

4.Extended Service Life: The oil-immersed transmission mechanism offers a considerably longer service life when compared to conventional mechanisms. Unlike traditional systems that often suffer from wear and tear due to poor lubrication, the oil-immersed transmission mechanism prevents such issues. It eliminates the risk of component failure, particularly in critical parts like bearings, ensuring optimal performance and longevity.

3.Cutting sample

The cutting speed of our mini waterjet cutting machine can vary based on factors such as the material type, thickness, desired cut quality, water pressure, and the specific configuration of the machine. While it's important to note that these speeds are provided as a reference for PMT waterjet machines, actual cutting speeds may differ.

Please keep in mind that optimal cutting speed should be determined based on your specific requirements and the characteristics of the material being cut.

One standout feature of the PMT Waterjet Cutting Table is its gantry mechanical structure. This design is perfectly suited for large-sized machines, allowing for extended travel distances along the X and Y axes. This versatility makes it particularly suitable for processing a wide variety of complex, oversized parts. Whether you're tackling intricate designs or sizable projects, the PMT Waterjet Cutting Table is up to the task.

PMT waterjet cutting machine Advantage

1.Smooth cutting quality is perfect.

2.The cutting accuracy of waterjet cutter is up to 0.1mm. Edge joints are regular, and waterjet cutting can also make very complex puzzles and murals.

3.Cutting speed is fast, and product consistency and interchangeability are very good.

4. Drilling, cutting and forming can be done at once.

5. Improve the working environment and reduce the impact of dust and noise on the operator.

6. Waterjet cutting is a cold cutting that does not damage the internal structure of the material.

7. It is the only machine for processing composite materials and fragile porcelain.

8. Waterjet Cutter can cut metal, rubber, foam, plastic, composite materials, stone, ceramic tile, marble,glass, etc.

About size, we have 4000*2000 mm , 3000*2000mm , 2000*1500mm , 2500*1500mm , 6000*2000mm ect, which you want?

Our laser edge finder, which slides over the focusing tube, allows the machine operators to rapidly establish exact location points, edges, centers of material, and centers of holes of pieces being cut on their Semyx Cutting Solutions' table.

1. Working Table & Controllor

The cutting table is a computer-controlled 2D table, featuring the Y-axis, catcher, X-axis, Z-axis (cutting head holder), cutting head, high-pressure hose, and the abrasive box. Both the X-axis and Y-axis are equipped with linear guides and ball screws for precise motion control.

Model | 2015 | 2515 | 3020 | 4020 | 6020 |

Dimension(mm) | 2650*2150mm | 3100*2150mm | 4500*2300mm | 5250*2300mm | 7000*3100mm |

Max. cutting range | 2000*1500mm | 2500*1500mm | 3000*2000mm | 4000*2000mm | 6000*2000mm |

Travel of Z axis | 180mm | ||||

Servo system | Weihong,OEM Panasonic | ||||

ball-screw linear-rail | ABBA/TBI,Taiwan Brand | ||||

Re-positioning accuracy | ±0.025mm/m | ||||

Cutting accuracy | ±0.1mm | ||||

Max. running speed | 15m/min | ||||

lubrication | Oil Immersion | ||||

Material | 203stainless steel material tank,cast steel beam,rubber and stainless steel cover | ||||

2. Feature

The guide rails and ball screws of our waterjet cutting tables are fully immersed in an oil tank, ensuring optimal lubrication and preventing wear caused by abrasive materials and water splashes. This unique feature not only guarantees exceptional cutting precision but also significantly prolongs the machine's lifespan. It effectively addresses the issue of accuracy deterioration commonly observed in conventional water jet cutting machines. Furthermore, our cutting technology ensures consistent accuracy regardless of the time of day.

1.Enhanced Stability: Our waterjet cutting tables employ an oil-immersed transmission mechanism that offers superior stability compared to traditional transmissions. This advanced system enables precise control over cutting speed, pressure, and direction, ensuring optimal performance.

2.Reduced Noise: The oil-immersed transmission mechanism utilizes high-quality finished oil for lubrication. Unlike the grease or liquid lubricants used in conventional mechanisms, finished oil provides superior lubrication effectiveness while generating minimal noise. This results in a quieter operation during the cutting process.

3.Convenient Maintenance: Our waterjet cutting tables equipped with an oil-immersed transmission mechanism require simplified maintenance compared to traditional systems. The long-lasting lubrication effect of the finished oil significantly reduces the frequency of oil replacement, resulting in lowered maintenance costs.

4.Extended Service Life: The oil-immersed transmission mechanism offers a considerably longer service life when compared to conventional mechanisms. Unlike traditional systems that often suffer from wear and tear due to poor lubrication, the oil-immersed transmission mechanism prevents such issues. It eliminates the risk of component failure, particularly in critical parts like bearings, ensuring optimal performance and longevity.

3.Cutting sample

The cutting speed of our mini waterjet cutting machine can vary based on factors such as the material type, thickness, desired cut quality, water pressure, and the specific configuration of the machine. While it's important to note that these speeds are provided as a reference for PMT waterjet machines, actual cutting speeds may differ.

Please keep in mind that optimal cutting speed should be determined based on your specific requirements and the characteristics of the material being cut.