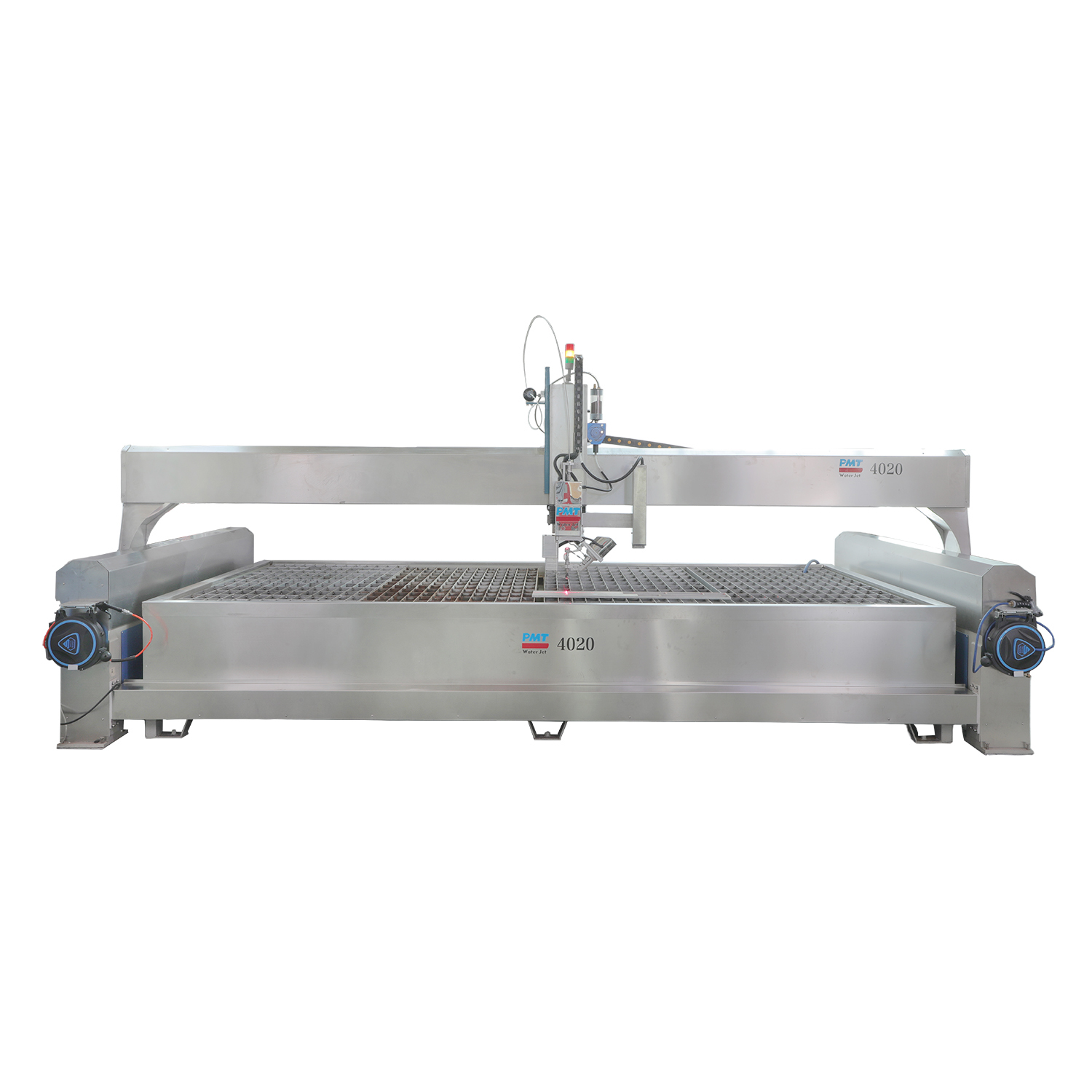

The AC axis of our waterjet cutting machine incorporates a sophisticated and precise height measurement system, enabling accurate and dynamic height control during the cutting process. This advanced feature ensures optimal cutting results and enhances the overall efficiency of the machine.

The height measurement system utilizes sensors and feedback mechanisms to continuously monitor the distance between the cutting nozzle and the material surface. This real-time measurement allows the machine to adjust the cutting height automatically, compensating for any variations or irregularities in the material.

With the AC axis height measurement system, operators can achieve consistent and uniform cuts, even on uneven or curved surfaces. The system detects changes in the material height and makes instantaneous adjustments to maintain a constant cutting distance, resulting in clean and precise cuts throughout the entire process.

Furthermore, the dynamic height control feature of the AC axis height measurement system allows for improved cutting speed and efficiency. The machine can adapt to different material thicknesses and densities, optimizing the cutting parameters accordingly. This not only saves time but also reduces material waste, making the cutting process more cost-effective.

The AC axis height measurement system is easy to operate and integrates seamlessly with the overall control system of the waterjet cutting machine. It provides operators with accurate and reliable height control, ensuring consistent cutting quality and enhancing productivity.

In conclusion, the AC axis height measurement system of our waterjet cutting machine offers precise and dynamic height control, resulting in superior cutting performance. With its advanced features and user-friendly operation, this system is a valuable asset for any cutting application that requires high precision and efficiency.

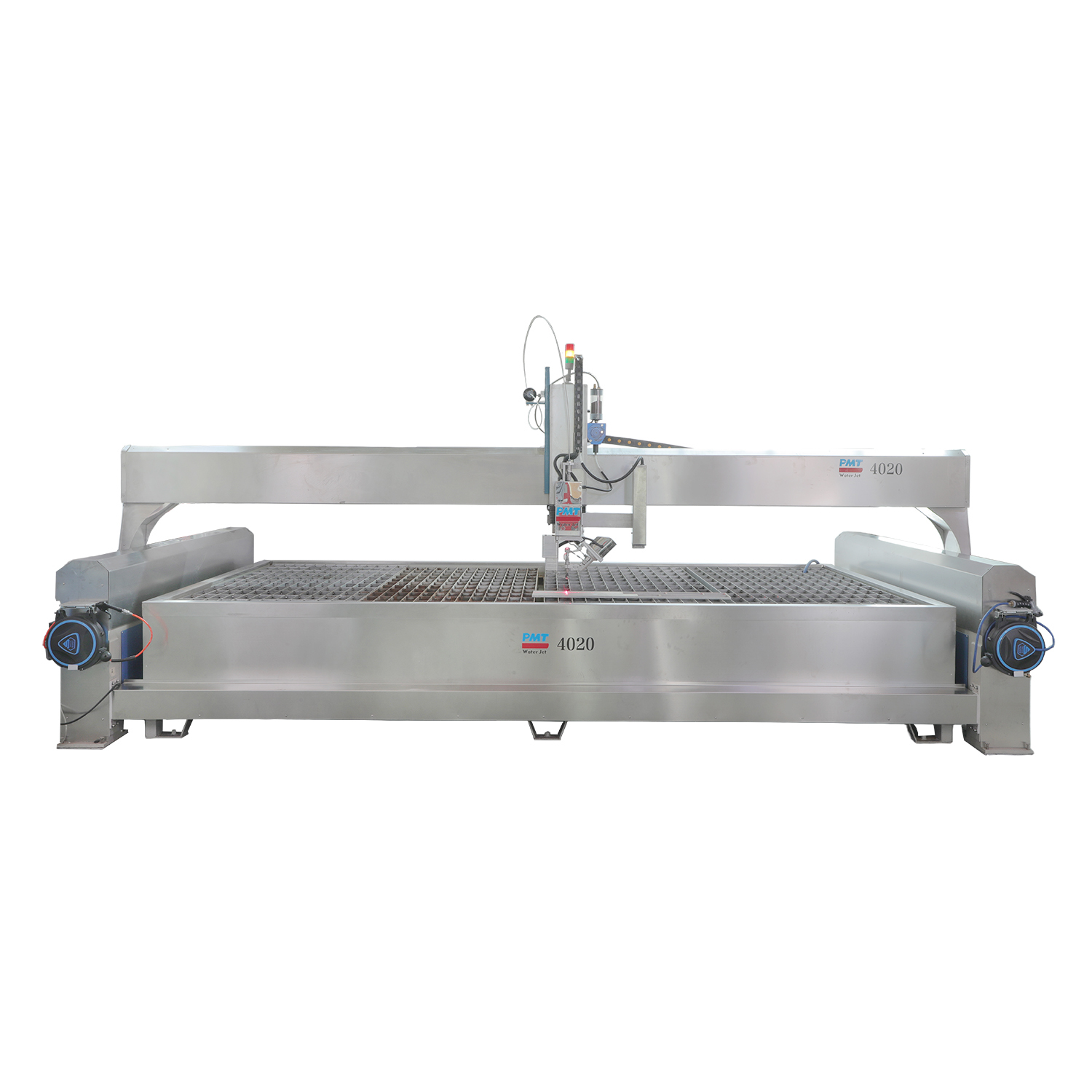

The AC axis of our waterjet cutting machine incorporates a sophisticated and precise height measurement system, enabling accurate and dynamic height control during the cutting process. This advanced feature ensures optimal cutting results and enhances the overall efficiency of the machine.

The height measurement system utilizes sensors and feedback mechanisms to continuously monitor the distance between the cutting nozzle and the material surface. This real-time measurement allows the machine to adjust the cutting height automatically, compensating for any variations or irregularities in the material.

With the AC axis height measurement system, operators can achieve consistent and uniform cuts, even on uneven or curved surfaces. The system detects changes in the material height and makes instantaneous adjustments to maintain a constant cutting distance, resulting in clean and precise cuts throughout the entire process.

Furthermore, the dynamic height control feature of the AC axis height measurement system allows for improved cutting speed and efficiency. The machine can adapt to different material thicknesses and densities, optimizing the cutting parameters accordingly. This not only saves time but also reduces material waste, making the cutting process more cost-effective.

The AC axis height measurement system is easy to operate and integrates seamlessly with the overall control system of the waterjet cutting machine. It provides operators with accurate and reliable height control, ensuring consistent cutting quality and enhancing productivity.

In conclusion, the AC axis height measurement system of our waterjet cutting machine offers precise and dynamic height control, resulting in superior cutting performance. With its advanced features and user-friendly operation, this system is a valuable asset for any cutting application that requires high precision and efficiency.