| Availability: | |

|---|---|

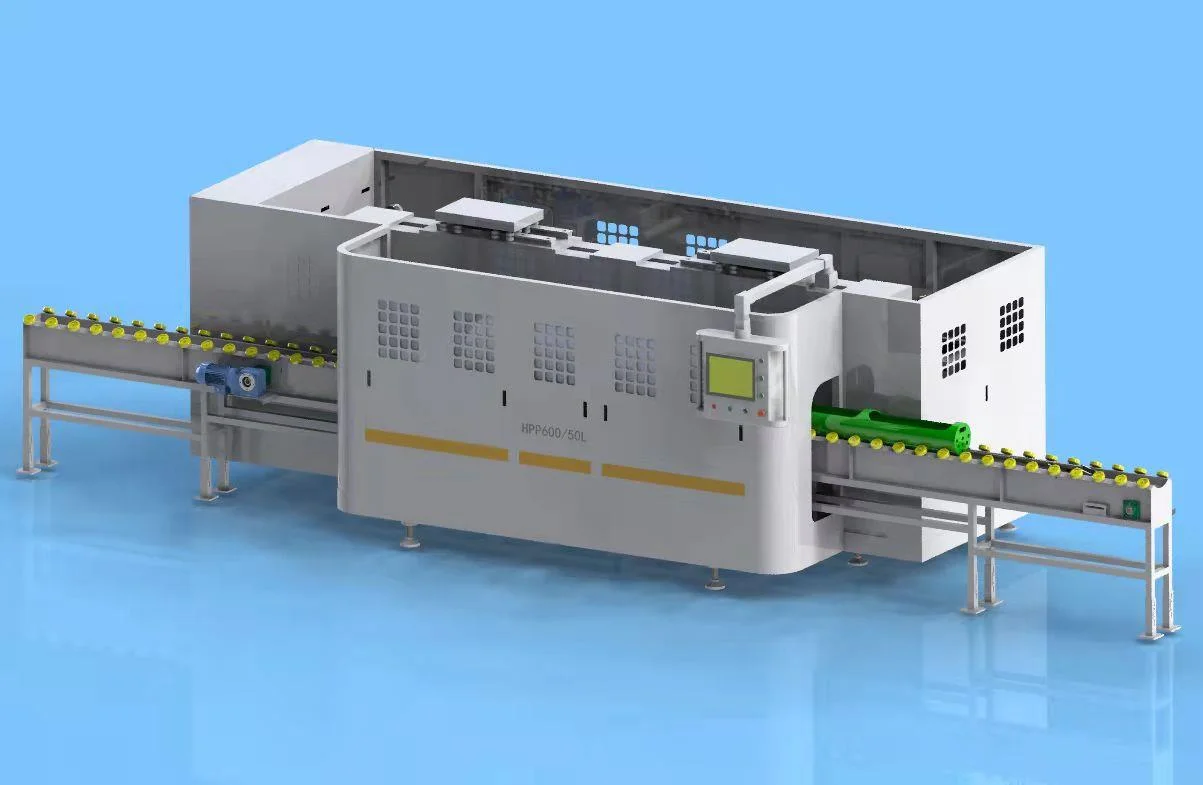

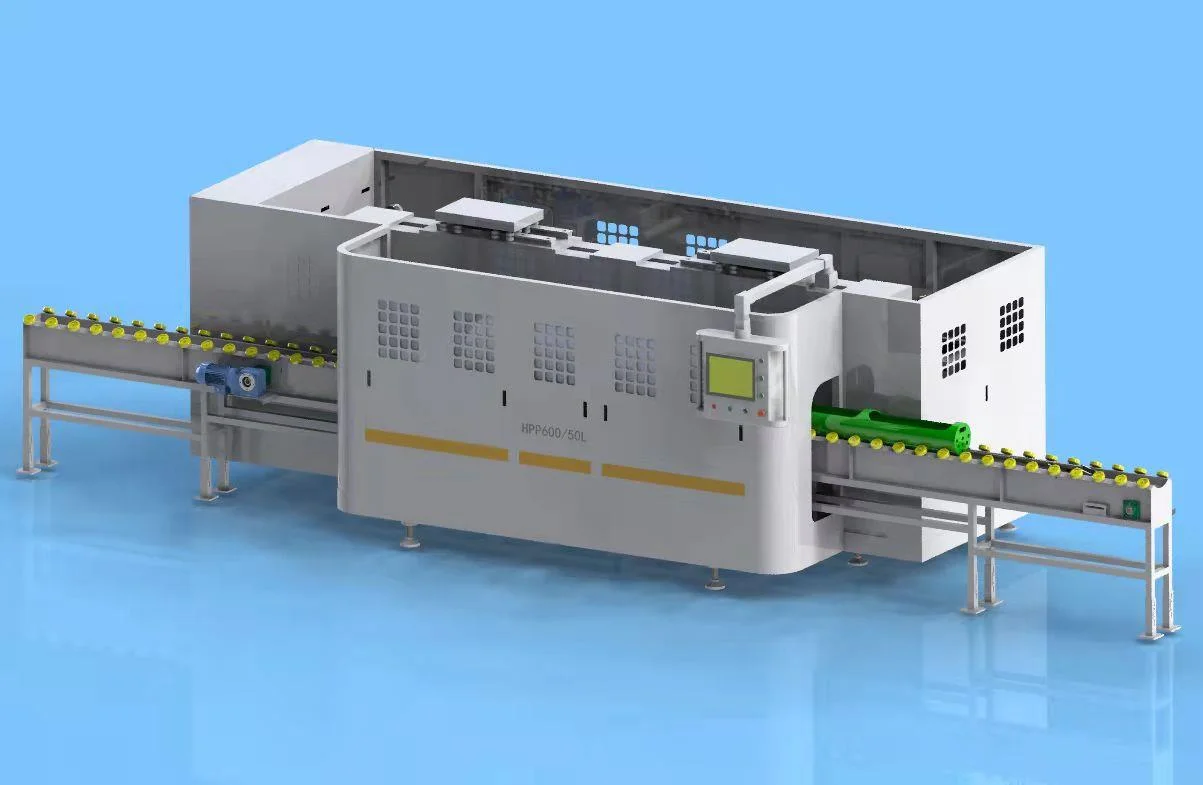

| Machine Model | HPP600MPa/50L 150L | HPP600MPa/350L 500L | ||||

| Vessel internal diameter | 50L/IDØ220 mm 300mm | 350L/IDØ400 mm 500mm | ||||

| Vessel Volume and Length | 3550L/1860mm | 350L/2800mm | ||||

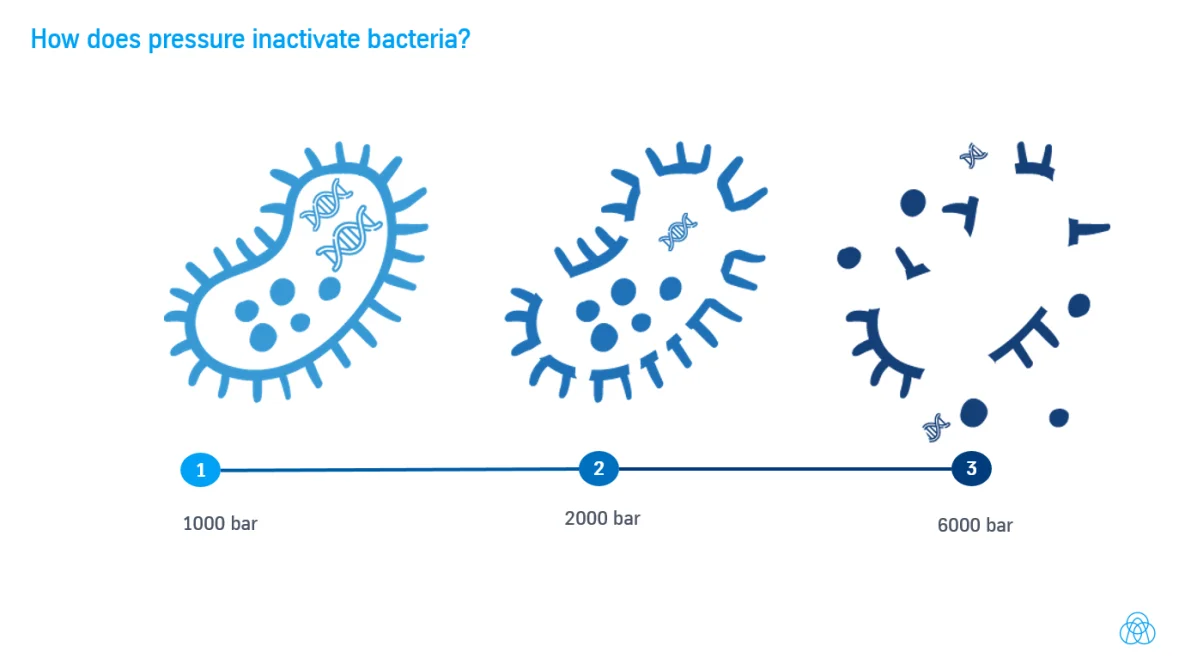

| Maximum working pressure | 600 MPa | |||||

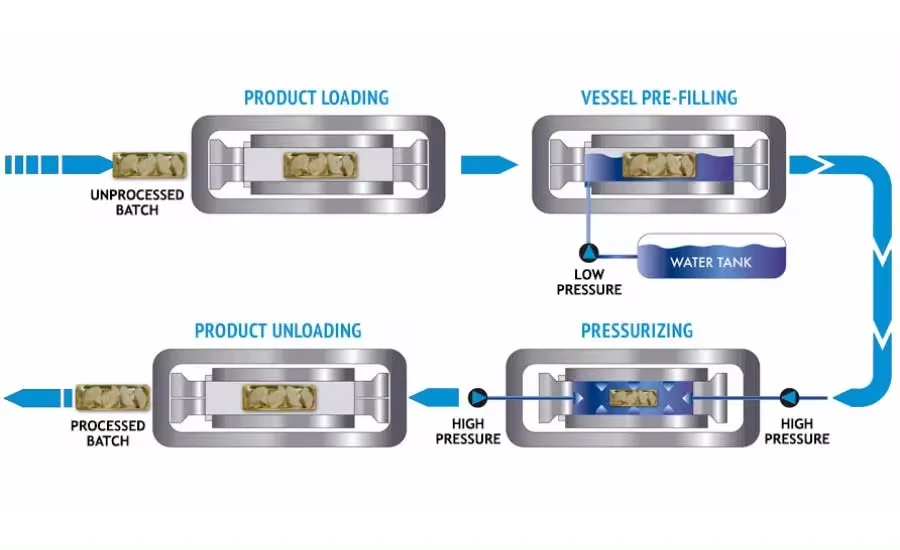

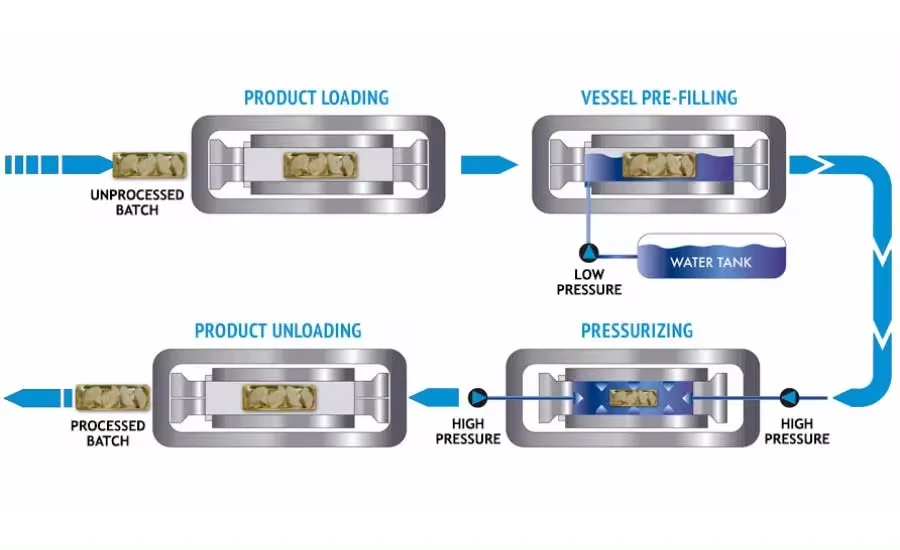

| Pressure time from 0-600MPa | 2-3 min | |||||

| Pressure transmitting fluid | Local drinking water (Purified water or R/O water will be better) | |||||

| Temperature for processing water | 5- 20 Degree Circulating Cooling Water | |||||

| Number of cycles per hour/ Production capacity | 6-8 cycles per hour (Depending on the holding time) | |||||

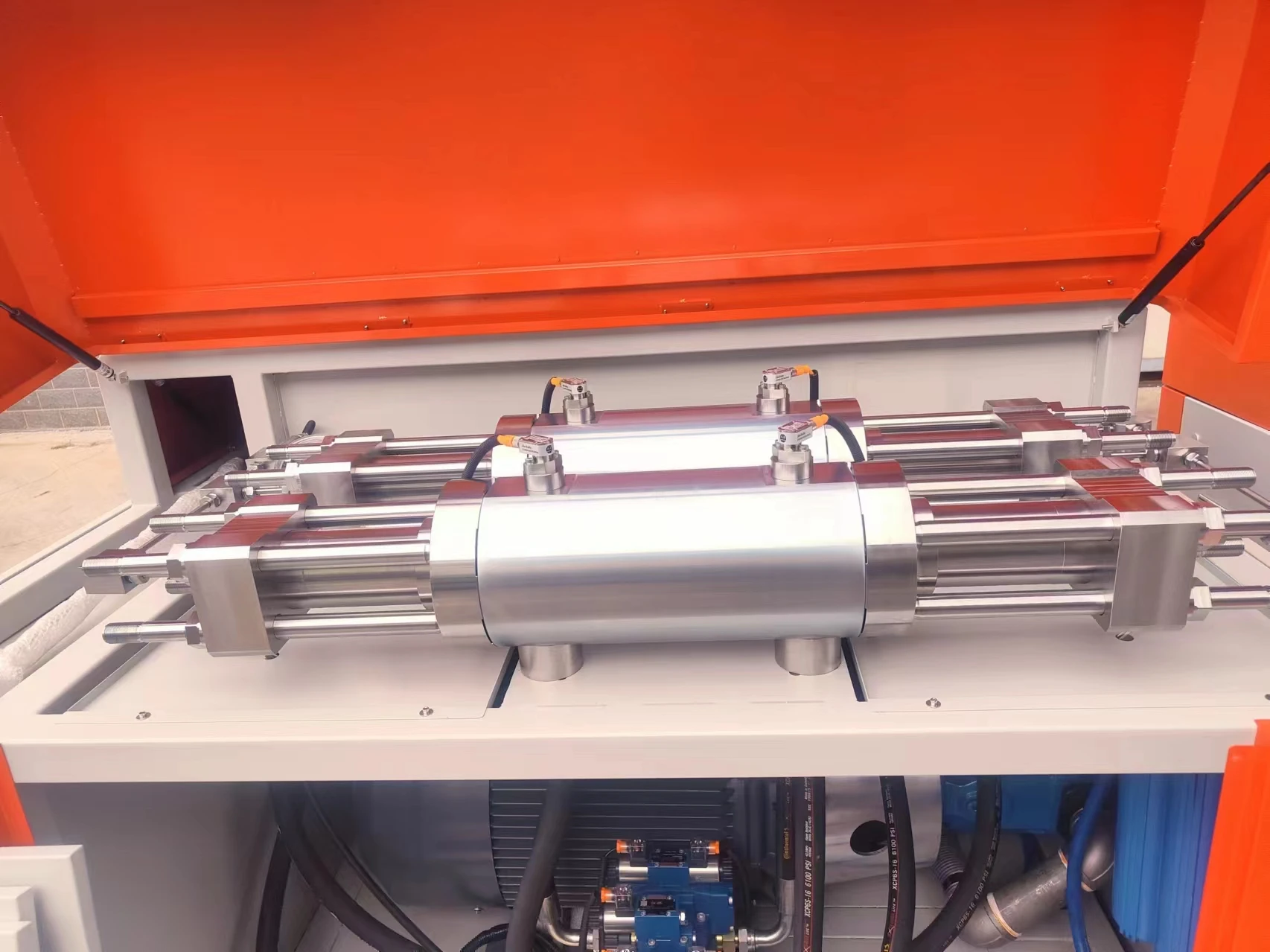

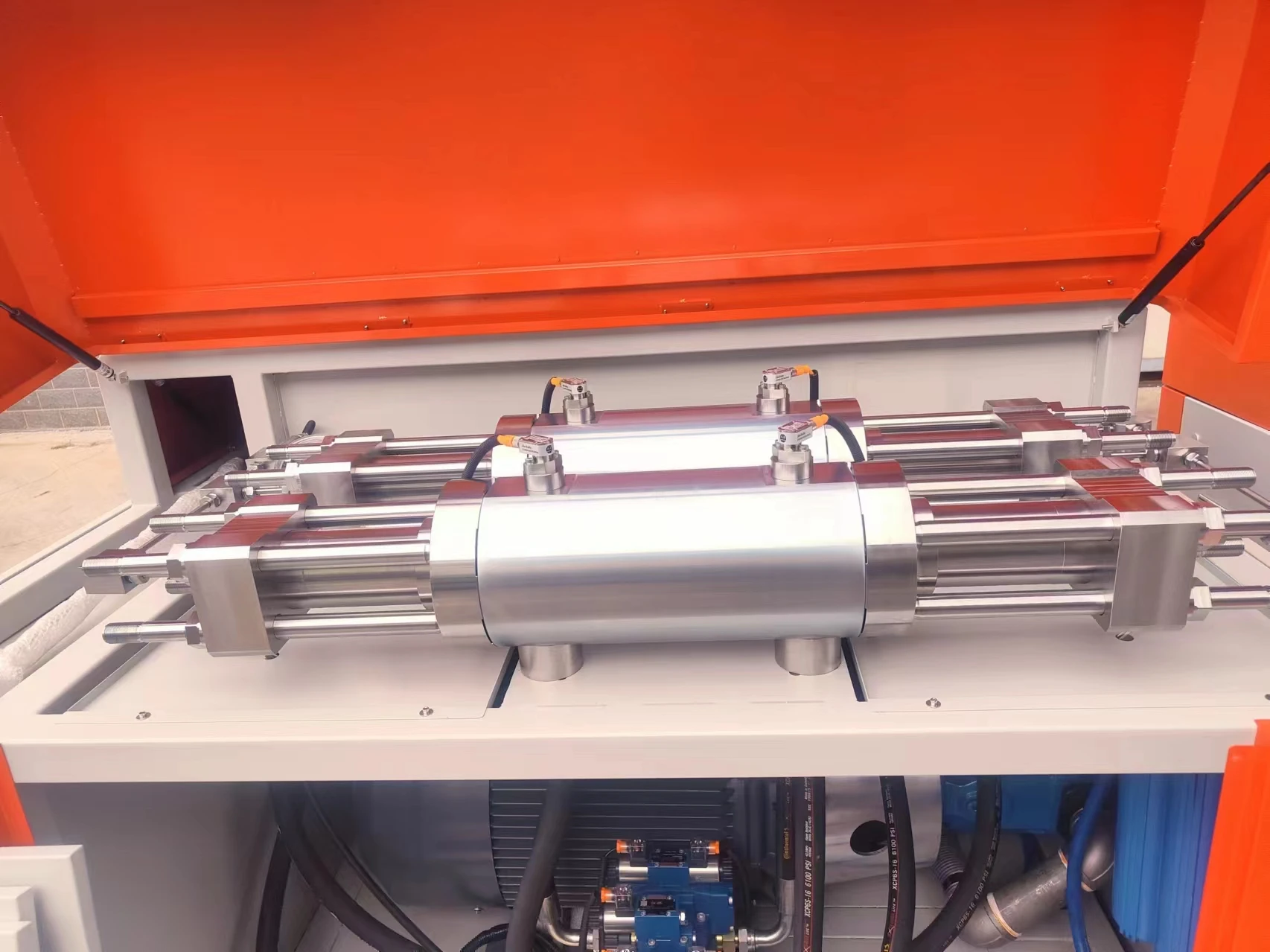

| Number of intensifiers | 50L/ 1 150/4 | 350L/8 525/12 | ||||

| Electrical Power | 50L/45KW 150L/150kw | 350L/350KW 525/500kw | ||||

| Sanitary food Design | All the stainless steel including machine outer cover are the 304 stainless steel for the machine | |||||

| Pressure Transducers | China Brand military technology reliable and durable | |||||

| Automatic loading and unloading line | Automatic conveyor loading basket enter vessel and output vessel for unloading basket | |||||

| Carriers basket for loading the product | Providing the food grade basket 4 -16 with the machine together | |||||

| Control Cabinet | Providing interntional standard control cabinet including ABB,Schneider and China famous brand electrical components. | |||||

| Control Mode | auto-control and freely setting high pressure processing parameters (Touch screen control pressure, temperature, time , Alarm indication , pressure curve etc datum with print, output, records etc function ) and provide international internet remote monitoring online service and diagnosis fault service . | |||||

| Certificates | ISO9001:2015; American ASME-U3 certificates; European PED 97/23/CE | |||||

| Warranty | Providing the whole machine service at least 2 years | |||||

| Vessel Warranty | Three (3) years without cycle limit | |||||

| Yoke Warranty | Six (6) years without cycle limit | |||||

| Spare Parts | At least providing 1 years main spare parts with machine together | |||||

| Installation, commissioning and training | After the machine arriving in customer’s factory, we will send our engineer to customer factory installation, commissioning and training for them carefully, the time will take about one week or so, you will provide our 2-3 persons accommodation during the stay in customer factory(during special situation like the pandemic,war etc , we will guide you how to operation the machine by WeChat video or internet remote monitoring online guiding installation and training service) | |||||

| Technical support | We will provide technical support and service at any time during customer using the machine. If the machine have problem in the warranty time, customer engineer could not fix the problem by themselves. we will fix the problem by WeChat video or internet remote monitoring online and diagnosis fault service | |||||

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Product application

| Machine Model | HPP600MPa/50L 150L | HPP600MPa/350L 500L | ||||

| Vessel internal diameter | 50L/IDØ220 mm 300mm | 350L/IDØ400 mm 500mm | ||||

| Vessel Volume and Length | 3550L/1860mm | 350L/2800mm | ||||

| Maximum working pressure | 600 MPa | |||||

| Pressure time from 0-600MPa | 2-3 min | |||||

| Pressure transmitting fluid | Local drinking water (Purified water or R/O water will be better) | |||||

| Temperature for processing water | 5- 20 Degree Circulating Cooling Water | |||||

| Number of cycles per hour/ Production capacity | 6-8 cycles per hour (Depending on the holding time) | |||||

| Number of intensifiers | 50L/ 1 150/4 | 350L/8 525/12 | ||||

| Electrical Power | 50L/45KW 150L/150kw | 350L/350KW 525/500kw | ||||

| Sanitary food Design | All the stainless steel including machine outer cover are the 304 stainless steel for the machine | |||||

| Pressure Transducers | China Brand military technology reliable and durable | |||||

| Automatic loading and unloading line | Automatic conveyor loading basket enter vessel and output vessel for unloading basket | |||||

| Carriers basket for loading the product | Providing the food grade basket 4 -16 with the machine together | |||||

| Control Cabinet | Providing interntional standard control cabinet including ABB,Schneider and China famous brand electrical components. | |||||

| Control Mode | auto-control and freely setting high pressure processing parameters (Touch screen control pressure, temperature, time , Alarm indication , pressure curve etc datum with print, output, records etc function ) and provide international internet remote monitoring online service and diagnosis fault service . | |||||

| Certificates | ISO9001:2015; American ASME-U3 certificates; European PED 97/23/CE | |||||

| Warranty | Providing the whole machine service at least 2 years | |||||

| Vessel Warranty | Three (3) years without cycle limit | |||||

| Yoke Warranty | Six (6) years without cycle limit | |||||

| Spare Parts | At least providing 1 years main spare parts with machine together | |||||

| Installation, commissioning and training | After the machine arriving in customer’s factory, we will send our engineer to customer factory installation, commissioning and training for them carefully, the time will take about one week or so, you will provide our 2-3 persons accommodation during the stay in customer factory(during special situation like the pandemic,war etc , we will guide you how to operation the machine by WeChat video or internet remote monitoring online guiding installation and training service) | |||||

| Technical support | We will provide technical support and service at any time during customer using the machine. If the machine have problem in the warranty time, customer engineer could not fix the problem by themselves. we will fix the problem by WeChat video or internet remote monitoring online and diagnosis fault service | |||||

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Product application